|

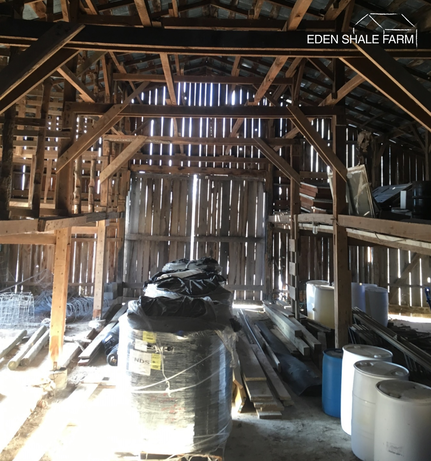

It has reached the time of year that I am tired of being hot. You walk out the door first thing and the muggy Kentucky mornings don’t even offer any relief. I routinely take an extra shirt with me to the farm so I at least have a dry one to drive home in. But it is Kentucky and it gets hot every summer, so we live with it and farm on. Right after the 4th of July we made our second cutting of alfalfa. After the first cutting we put some nitrogen down and with the continued moisture this summer it grew back good. It produced 49 more bales pushing our total in the hoop barn to 368 bales. Typically if we can get 400 bales in the barn we have enough to get through the winter given somewhat “normal” conditions. At the end of first cutting we were able to put hay into the new Barn Alley Feeder that Dr. Higgins designed and installed this past year. This feeder is built in the center alley of an old tobacco barn. It borrows the same self feeding concept as the Large Bale Feeder but is done so utilizing existing infrastructure. The custom sized wood feeder is hung from barn door track on each side and slides back as the cattle eat the hay. This feeding structure also serves as a hay storage facility as we were able to bale the hay and put it directly from the field into the feeder. This barn alley feeder will hold 30 5x5 round rolls of hay, and will serve as a storage facility until the first of the year when the cows will be allowed access to the hay. The 30 rolls of hay should be all we need in this location which means the tractor doesn’t have to come refill the structure until we bale more hay next season. Utilizing this structure we have gained additional storage capacity and increased our efficiency of time as we have eliminated the need to haul the hay to the hoop barn and then back to the cattle to feed it. The hay is stored in the same location as it is consumed. I am excited to feed with this new facility this winter. On July 8th we worked all of our spring calves for the first time. They got vaccinated for respiratory/pasteurella, blackleg/somnus, and pinkeye (cultured from a local strain). They were also dewormed and fly tagged. We also castrated (knife cut) and implanted the bull calves. And lastly, all the calves got a high frequency EID tag. This is part of a retention study we are doing to see how well this visual/EID tag stays in their ear. Yes, it was hot that day to work cattle. But we started early and turned the pairs back out to shade and water before the heat of the day. And I guarantee you that I wore that extra dry shirt on the way home! Stay cool out there! There are many buildings on farms which were used long ago, but do not contribute much to a farming operation today. However, with planning concepts, these buildings can be repurposed or "reprogrammed" to contribute to the farming operation. The old tobacco barn at Eden Shale is one of those situations. (Figure 1) Reprogramming is used to repurpose to a building when it can no longer be used for the purpose for which it was originally intended. The old tobacco barn was specifically designed to house and cure tobacco. The decisions and design were developed to serve that particular function and nothing else. For example, the ventilator doors were designed to dry the tobacco and bring it in case, while the columns and rails were spaced for hanging the tobacco. The structural life of a building is expected to be at least 100 years, but the intended use of the facility might be changed two or three times during the life of the structure. In this case, a tobacco barn that was inefficiently being used was reprogrammed for hay storage and feed. This combines two practices, creating an integrated system by using efficient hay feeding concepts and concepts of an ideal hay feeder.

There are two main objectives we try to achieve at Eden Shale: (1) repurpose old facilities or materials into new practices and (2) implement labor saving practices. An ideal labor-saving system combines multiple practices that directly and indirectly benefits the operation. The direct benefits of labor saving designs are:

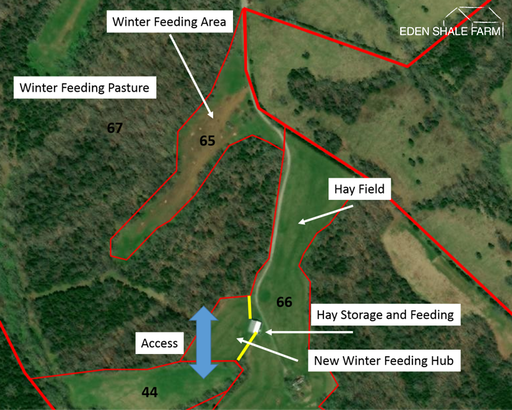

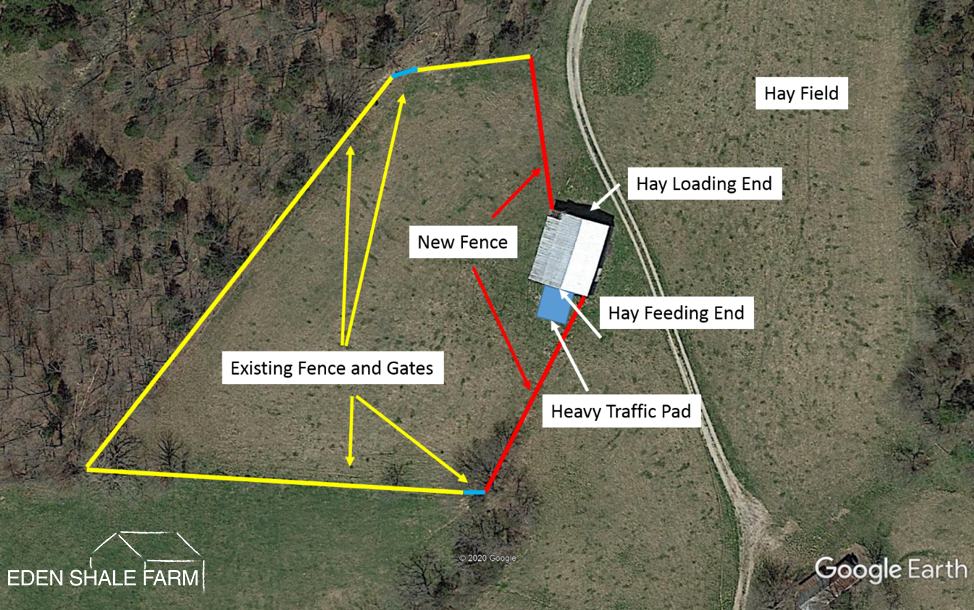

After tobacco left Eden Shale, the barn was primarily used for extra storage (Figure 2). This barn is located on a 25-acre endophyte free fescue hay field, just around the corner from our winter feeding area (Field 65), which contains the large bale feeder (Figure 3). However, there is not enough space at the large bale feeder in Field 65 to accommodate the entire herd. With this in mind, Dr. Higgins proposed a plan to “reprogram” the old tobacco barn into a self-feeding hay system with hay storage. We isolated the barn from the hay field by installing two sections of fence (approximately 300 feet), from the corners of the barn to two corners of an adjacent wooded area and pasture (Figure 4). Cattle currently utilize the wooded area (Field 65) in the winter as a shelterbelt, thereby reducing feed and maintenance requirements, and stress on the heavy pregnant cattle. Reprogramming the barn in Field 66 to a hay storage and self-feeder in the adjacent pasture field, provides an added bonus for moving the cattle to a fresh field, which will also have access to the reprogramed barn. The self-feeding hay feeder was created by using the existing center alley, support columns, and concrete floor (Figure 5). The feeder design utilizes an under-hung crane concept. This design suspends the feed panel (made of wood) and allows the panel to travel from one end of the barn to the other. Hay is loaded into the barn (capacity of approx. 30 bales) from the northern end, while the cattle will access the hay in the feeder from the southern end of the barn (Figure 6). The southern exposure will provide a dry surface and experience for the cattle. The design of the feeder reduces hay waste by creating separation between the cattle and the hay (Figure 7). (Strings are removed at the time of storage.) The capacity of the barn and the size of the herd enables the cattle to self-feed themselves for approximately 25 to 30 days. In addition, the approach to the feeder will be constructed of a heavy traffic pad made from geotextile fabric and rock. The benefit of this layout is that the distance between the hay field and hay storage has been reduced significantly, compared to the previous storage practice. Storing the hay inside also reduces the degradation of the nutritional quality of the hay and eliminates the need to move bales from one the previous storage location to the feeder. This in effect eliminates the time, labor, and need to relocate the bales and reduces the hay waste that may have occurred in moving the bales. Overall, the reprogramming project eliminated distance traveled and since the reprogrammed barn is situated in the hay field, there are no gates that have to be unlatched opened, closed, and re-latched, forcing the tractor operator to dismount and mount the tractor. From a whole farm perspective, this project leverages a structure and an area of land into an organized hub. It creates a permanent feeding location using a fixed structure, which also allows for hay storage. With this project, we were able to repurpose an old facility into a new practice, while implementing labor saving practices. This was not only an effective design for reprogramming an existing barn, but it was an intelligent design done at minimal cost. For more information, including designs and list of materials, click the button below to be taken to the Barn Alley Feeder page.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed