|

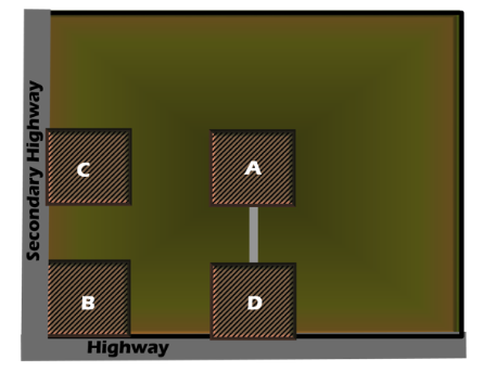

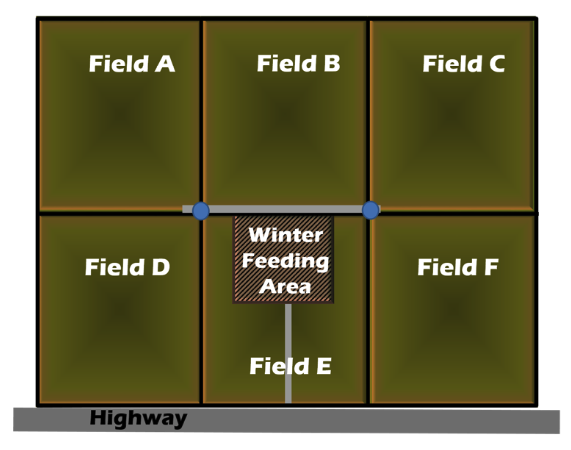

Dr. Steve Higgins, University of Kentucky Structures for beef cattle fall into two categories: simple shelters and buildings. Simple shelters are used where little preparation needs to be done, or can be afforded, other than to provide cattle with the simplest type of protection from wind and sunshine. Examples of simple shelters are windbreaks, shade structures, trees, and topography. Simple structures may be enough for cattle when a forage analysis indicates they are being fed a proper ration. However, winter-feeding creates soil erosion, mud, compaction, and loss of vegetation due to cattle pugging and vehicle traffic. Waste of harvested forages also has to be removed and additional material has to be fed, which means greater distances must be traveled. Additionally, winter feeding has additional costs, including time, fuel, seed and chemicals needed to renovate winter feeding areas. Using a cost-benefit analysis, it would be hard to justify the expense of new buildings based on economic benefits gained from feed efficiency, average daily gain, or health. Nevertheless, indirect benefits can matter to producers, who count the aforementioned benefits as well as benefits obtained from ease of management, environmental compliance, and personal judgement. However, not all buildings are the same, nor is the management of them. Livestock housing, whether simple or sophisticated, must perform the required functions. It should meet the thermal and physical needs of the animal; it should provide a place to store and feed materials without damage or loss; it should increase the performance of cattle; and, it should allow the producer to conduct all chores associated with cattle production efficiently. A building can contribute to management efficiency and animal performance, which itself is defined by productivity, health and welfare. The building should create optimum environmental conditions for cattle by providing light, air flow, appropriate flooring, space, and ventilation. To provide shelter from summer sun but also provide the warmth of the sun in winter, the layout of the building and the location must be based on compass points. An east-west orientation of a building is usually desirable for the following reasons. It creates a maximum surface area to the south for winter swarming. Sunlight is one of the cheapest and most effective disinfectants known to man. Allowing sunlight to enter the facility to disinfect surfaces is a good management practice. An east-west orientation also maximizes shade during the summer. Orienting the building based on compass points can also create optimum ventilation and save energy by using prevailing winds. Good ventilation is of paramount importance in housing, with ruminants particularly prone to respiratory ailments if good ventilation is not provided. The siting of the building should take advantage of cool summer breezes, while protecting cattle from harsh winter winds. Flooring should provide drainage, be non-slippery, and make manure removal easy, while providing space for the animal to move, eat, drink, and lie down. The layout should allow the producer to move or separate animals for easy care and handling. The building should accommodate existing or planned equipment for the easy removal and storage of manure and bedding. Livestock waterers should be accessible to cattle, yet out of the way during manure removal, while reducing the contribution of wetness to flooring and bedding, and be easy to clean. Buildings need to be accessible to the producer and the cattle. Ideally, a building should be located along a road near the approximate center of the operation or in the middle of the operation. Figure 1 shows four locations for a farmstead. The center of the operation “A” is the best option. It allows the producer to expand in four different directions and it provides an equal distance to each corner. The second-best locations are “C” and “D”, which are essentially the same just different highway usage. The location of a farmstead on the corner at “B” is probably the worst location. One reason is that it requires the longest distance to travel to the opposite corner. It also limits the ability to expand the operation to two directions. Lanes should be created to provide access to the fields and the buildings. Figure 2 shows how a lane allows the cattle to be moved from one field to another without going through a third. Cattle in any field can also be moved back to the winter feeding area or handling area without going through a second pasture. Watering stations can be placed at the intersections of these fields to facilitate rotational grazing and access.

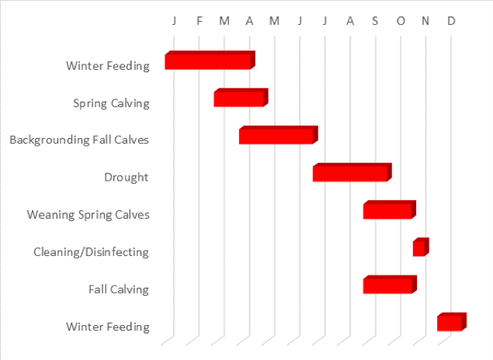

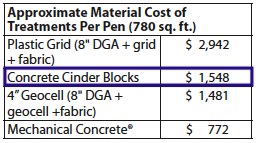

Summary A systems approach that incorporates all aspects of animal and worker performance is needed for effective cattle buildings. Two basic purposes of buildings are to provide an optimum environment for cattle production and to assist the stockman with management. Management ease is accomplished by incorporating feed storage and handling as well as manure storage and handling. The tasks of feeding and removing manure require the greatest amount of labor and time. Adequate ventilation is needed to control heat, moisture, and contaminants. The key to making a building contribute to the operation is perspective. If we call our buildings “barns,” then what will we use them for and how will they be valued? Conversely, if we look at a building as a food production center, which it is, then we should have a better perspective on its contribution. The reality is that cattle occupy buildings that were built generations ago when we didn’t know as much about the thermal and physical needs of cattle; the layout of the building was probably not designed for the efficient removal and storage of manure; the design was probably compromised to reduce cost; and the site was probably selected based more on social reasons than on engineering concepts, environmental stewardship or animal care. That type of cattle housing, where cattle occupy a man-made environment not centered around production, represents a compromise between cost, operating convenience and animal performance. We can do better. In order to provide value, a static structure must become a dynamic structure that contributes to management efficiency and animal performance, which is defined by three objectives that should always go together: productivity, health and welfare. Floor Type #4 - Cinder Blocks The cinder-block treatment was created by laying down filter fabric, placing the blocks (open end up), and then backfilling with dense grade aggregate (DGA). This treatment should provide a 49 percent pervious surface. The surface of the blocks acts as the final edge or surface to facilitate manure removal with a bucket loader but without removing rock. The cinder-block flooring treatment was the most labor intensive treatment with each block weighing approximately 30 lbs. After a few days, the surface of the DGA showed a noticeable amount of dampness (see image below). In addition to providing infiltration, cinder blocks absorb moisture from the environment. The blocks are analogous to a sponge as they wick moisture from the atmosphere or environment. A bench top lab study suggested that each block could store one-gallon of liquid. The observation of moisture does suggest that a disadvantage of this flooring might be that it draws moisture to the surface, near a lying animal and bedding. Additional observations and measurements would need to be collected to determine the outcome of this effect. Summary This case study demonstrated four floor designs for housing cattle that meet the animals’ needs while facilitating manure removal, storage and handling. All of the treatments—four-inch geocell, plastic grid, Mechanical Concrete®, and concrete cinder blocks—would last longer than a fabric and rock pad. However, the concrete block flooring showed significant dampness and, because of the weight of the blocks, was hard to manage and labor intensive. Both the geocell and plastic grid were more expensive initially than other options but drained well, which would reduce bedding costs over time. Mechanical Concrete® was the easiest to install and was very cost-effective considering the additional years it could add to a fabric and rock underlayment.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed