|

By Dr. Steve Higgins When I was in school, I remember hearing a story. It was a long time ago and I can’t remember if it was true or not, but I’d like to think that it was. There was this student, in the College of Ag, that was informed that he did not have to attend class on Labor Day because it was a holiday. When he was growing up on the farm, his dad was adamant that Labor Day was the time to work as hard as possible fixing things; painting, cleaning, hauling away trash, and straighten up everything on the farm. The young man was surprised to learn that his friends and their families were going to spend their Labor Day going to the lake and cookouts one last time before summer ended. The student commented that when he got home, he was going to have a conversation with dad. The point that I want to make about this story is that we should set aside time to maintain our properties. I realize we are constantly fixing things to keep working, such as equipment, fences, and gates. It’s what some would call “putting out fires”. However, I’m talking about a different strategy. If we don’t replace a few nails on a roof panel, it could break loose and take several more with it. Neglecting a rotten support post could undermine the structural integrity of a building. The difference between the two scenarios is that the first approach is to operate something until it breaks, then repair it, while the second approach is to reduce the risk of equipment, machines, and buildings from failing through preventive maintenance. Benjamin Franklin is known for saying “an ounce of prevention is worth a pound of cure”. Nevertheless, we never seem to have time or make time to conduct inspections of our properties. To that end, we need to schedule time to do preventive maintenance. If a maintenance schedule is not adequately planned, the cost of maintenance becomes abnormally high. Only a systematic approach to maintenance can reduce this cost. Preventive maintenance or correction of defects not only decreases repair costs, but it also promotes safe operations while maintaining the function and capacity of machinery, equipment, and structures. Emphasis should be placed on the following areas: building construction and maintenance, mechanical equipment maintenance, electrical equipment maintenance, farm safety, fire and theft protection, and yard and ground maintenance. Let me give you three examples of maintenance. Example 1: The photo below is a wire pile that was located on the Eden Shale Farm, this wire pile wasn’t contributing to the operation. In fact it was taking up valuable space. As farmers, you always want more acreage for new projects, improvements, or expansion. We need to take a look around to see what areas of our farms we can clean up to allow for usage of those acres towards production of the farm. When we applied this concept to Eden Shale and removed this pile of wire and sold it for scrap, the proceeds ($3,600) were then applied to the subsequent structure placed at the site, which ended up being the large hay feeder and allowed for a new winter feeding site for heavy bred cows at Eden Shale. Example 2: Sometimes maintenance can be combined with alterations. The Bull Barn, on the Eden Shale Farm, has deteriorated support posts, roof nails that have worked their way out, rusted out and obsolete bunk feeders and waterers, dirt flooring, inadequate ventilation, and zero manure storage. Some of this is a result of deferred maintenance, economics, and planning. Some of it is due to design flaws because we didn’t know as much about flooring and ventilation in the 60’s when the barn was built as we do now. Instead of conducting repairs to outdated designs, we are modifying features to coincide with new knowledge and management objectives. Modifications are currently being conducted to facilitate and improve manure removal, forage and concentrate feeding, watering, and ventilation. Refurbishing will replace rotten posts, deteriorated panels, and permanently damaged flooring with multiple designs and modern labor saving practices, which can then be demonstrated for producers. In this example, repairs are combined with alterations as one coordinated project to create a more functional facility. Example 3 Lastly, no design is perfect. The Eden Shale Farm has numerous demonstration projects that have been added since 2013. In addition, we are constantly adding new demonstrations, while simultaneously updating previous projects by improving them with automation, tweaking, and fixing design flaws. For example, float switches have been installed to turn water pumps on and off automatically. Another is adding additional water storage to match herd numbers and grazing requirements. Why are we doing this? Because we have learned from mistakes, found better ways of doing things, and are motivated to create a more efficient processes. We can all agree that there is plenty of work to do. Automation means a worker can be replaced with machines, meaning we do not have to worry about controlling certain things, which enables us to focus our attention on other things. It turns out that Labor Day is the celebration of the American labor movement and the contributions that workers have made to the development, growth, endurance, strength, security, prosperity, productivity, laws, sustainability, persistence, structure, and well-being of the country. (Yes, I had to look it up). It is celebrated by a long weekend. You may not want to give up your Labor Day, but I can’t think of a better occasion. Your hay is already up, fields have been mowed, and crops are still growing or starting to senesce. It might be the most appropriate time to work as hard as possible fixing things, painting, cleaning, hauling away trash, and straightening up everything on the farm to make it more presentable, productive, and prosperous. Maybe dad was on to something.

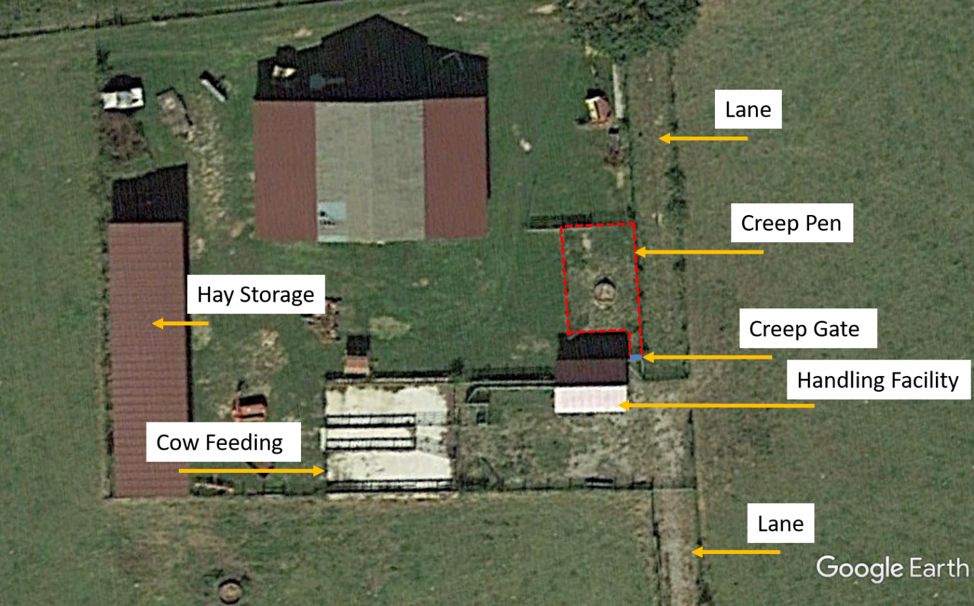

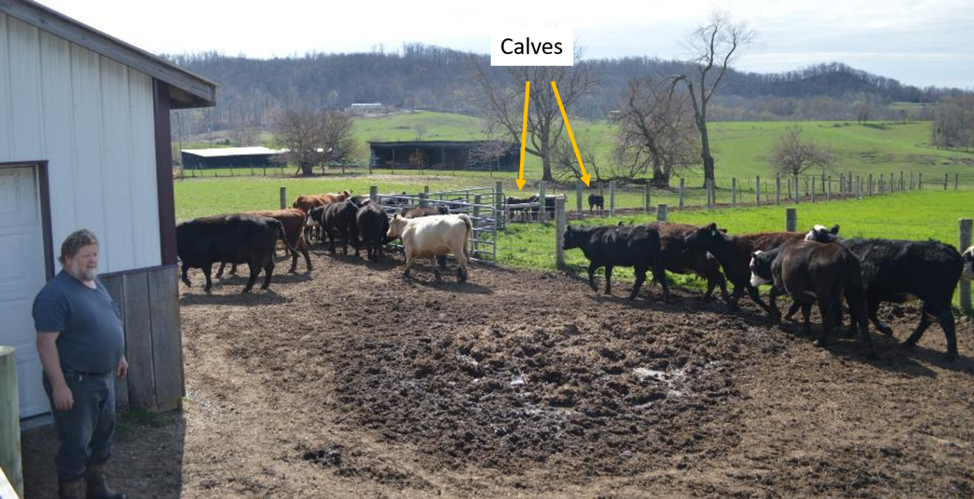

By Dr. Steve Higgins Over the past two years, producers have seem more mud and production losses than they ever want to see in their life. The ripple effect from above average rainfall and moisture is still having negative impacts on production. Production issues that impacted beef cattle producers the most were mud, mortalities (both calves and cows), body condition score loss, wasted feed, erosion, torn up fields, poor hay quality, poor feeding areas, and weak calves. One possible production solution that could address several of these issues is the implementation of calf pens and pastures created using creep gates. Creep gates are traditionally used to provide supplemental feed to calves. Creep gates are designed to exclude large stock but allow calves access to a feeder, pen, or pasture. The implementation of a creep pen or pasture can provide calves a dry area to escape mud, lay down, and reduce the risk of trampling from adult cattle. Within this creep area a producer could provide access to a shelter area that could have a roof. The concept is to provide a well-drained area for calves with or without supplemental feed, without their moms having access. The important components that it should provide are dry bedding, grass cover, heavy traffic pads, or any surface which provides comfort to the calves. More flexibility is obtained by providing multiple options, which also increase the benefit-cost ratio. Calves have the instinctive behavior to seek dry places to camp. These camping places are typically the wasted hay areas round feeding areas (Figure 1). Lying down in feeding areas occupied by cows can lead to the injury or death of a calf. The idea of a calf pen or pasture is to provide a safe place to camp that is away from mud and larger, inattentive stock that could accidentally step on them. Figure 2 is a layout for a cow-calf operation that incorporates a centralized feeding area. The incorporation of lanes or animal trails and gates allows these feeding areas to be accessible by six different pastures. The incorporation of hay storage, handling facilities, and feeding structure creates a centralized operations hub, which provides organization, efficiency, and simplicity. Equally important in that the layout provides a creep area for calves adjacent to the winter-feeding structure for cows figures 2 and 3. This means that as cows come up to feed, the calves have the opportunity to cleave off and go into their own area, which allows the cows to feed without having calves under foot (Figure 4). When the cows leave the centralized feeding area, to return to one of the six pastures, the calves rejoin the cows using the lane (Figure 5). The creation of a creep pen or pasture area can be accomplished using various methods and materials. The economy of materials can allow a producer to implement an area with a minimum of expense. The cost of one fallen calf could pay for the implementation of the practice. Design components should include a dry, well-drained area. The area may provide supplemental feed, which could be a part of a pre-conditioning or pre-weaning program. Ideally, the structure should be accessible to multiple pastures to increase utilization and management options. At the very least, it should be accessible from the pasture that is typically used for calving or where calving is planned as part of a new layout. Providing access from an all-weather surface lane is not only ideal, but a necessity when multiple gates are located in close proximity. The lane should be designed to be as short and as narrow as possible to economize the gravel and geotextile fabric used to construct heavy traffic pad surface.

This type of practice may not be as beneficial to fall calves as spring, however, this is the time of the year to build it. |

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed