|

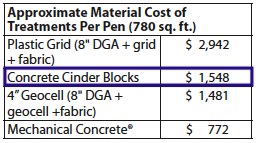

Floor Type #4 - Cinder Blocks The cinder-block treatment was created by laying down filter fabric, placing the blocks (open end up), and then backfilling with dense grade aggregate (DGA). This treatment should provide a 49 percent pervious surface. The surface of the blocks acts as the final edge or surface to facilitate manure removal with a bucket loader but without removing rock. The cinder-block flooring treatment was the most labor intensive treatment with each block weighing approximately 30 lbs. After a few days, the surface of the DGA showed a noticeable amount of dampness (see image below). In addition to providing infiltration, cinder blocks absorb moisture from the environment. The blocks are analogous to a sponge as they wick moisture from the atmosphere or environment. A bench top lab study suggested that each block could store one-gallon of liquid. The observation of moisture does suggest that a disadvantage of this flooring might be that it draws moisture to the surface, near a lying animal and bedding. Additional observations and measurements would need to be collected to determine the outcome of this effect. Summary This case study demonstrated four floor designs for housing cattle that meet the animals’ needs while facilitating manure removal, storage and handling. All of the treatments—four-inch geocell, plastic grid, Mechanical Concrete®, and concrete cinder blocks—would last longer than a fabric and rock pad. However, the concrete block flooring showed significant dampness and, because of the weight of the blocks, was hard to manage and labor intensive. Both the geocell and plastic grid were more expensive initially than other options but drained well, which would reduce bedding costs over time. Mechanical Concrete® was the easiest to install and was very cost-effective considering the additional years it could add to a fabric and rock underlayment.

Comments are closed.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed