|

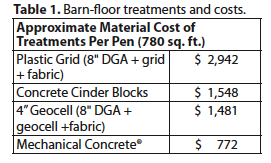

Dr. Steve Higgins, University of Kentucky Barn-floor design is critical to the physical and thermal comfort, health, and safety of cattle. Generally speaking, barn flooring is the surface on which an animal stands, lies down, and excretes its urine and manure. Therefore, to meet animal needs, it must be durable, not slippery, and well-drained as well as comfortable, warm, and dry. In addition to providing animal comfort, the flooring should easily be cleaned. No single material, from concrete to soil, meets all of these specifications. With these considerations in mind, a demonstration project at Eden Shale Farm, examined how four different materials could be used to provide comfort and make manure management and removal more effective, since one goal was to prevent a loader bucket from removing the rock flooring due to gouging into the flooring. This case study examines the positive and negative aspects of four different flooring options. Four barn-floor designs—a four-inch geocell, plastic grid, Mechanical Concrete®, and concrete cinder blocks—were demonstrated at the Eden Shale Farm. All of the treatments used filter fabric and rock (rock was used to provide infiltration, and filter fabric to provide reinforcement, friction, separation, and drainage.). Table 1 lists flooring treatments and material costs for each application. Rock and Fabric Filter The use of rock and filter fabric can reduce the cost of a flooring project. However, with aggressive and repeated scraping, rock can be removed, which means it eventually will need to be replaced. After repeated reapplication of rock, these types of surfaces can be just as expensive as concrete over time. When there is a layer of manure and bedding, it is difficult to get a reapplication of rock to adhere to the old surface. Filter fabric and rock pads will eventually fail. The estimated lifespan of a heavy traffic pad is about 10 years with proper maintenance. With this in mind, a goal of this demonstration project was to show how different materials could be used with filter fabric and rock pad to extend the life of the flooring. Floor Type #1 - Geocell Material A geocell product was available in four-inch and six-inch depths. The four-inch geocell material was used by laying down geotextile fabric. The geocell was stretched out and staked, using two-foot stakes. Adjacent geocell sections were tied together using zip ties. Dense grade aggregate (DGA) was backfilled into the voids (Figure 1). The geocell product walls seemed to be too flimsy for placing the rock. However, observations of the rock being placed showed that the geocell did hold up. How well it lasts will be determined later. Below is a picture of what the geocell material looks like before it is spread out. Stay tuned for the 3 other types of flooring used in our bull barn!

Comments are closed.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed