|

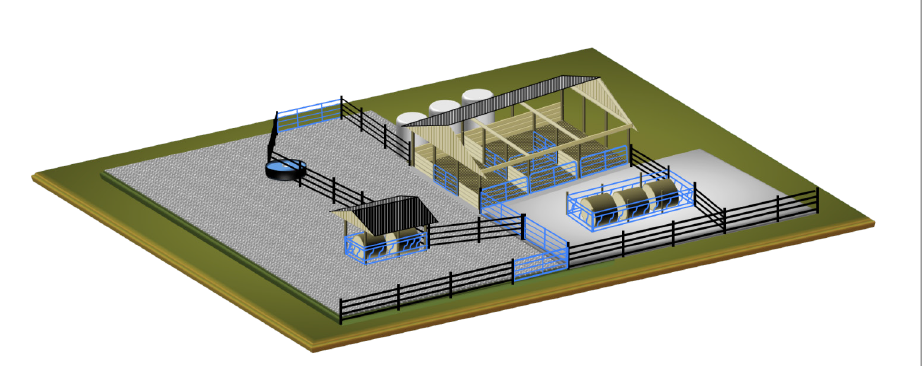

A few years ago, we began renovating the old dairy barn into a maternity/calving barn. Eden Shale hasn't had dairy cows since the 1970s, and the dairy barn wasn't designed for proper beef cattle management. . Much like the bull barn, the dairy barn had a number of issues - poor storm water management; poor flooring; inefficient use of space; under-utilization of existing concrete; no centralized water point; no lanes for access to multiple pastures, etc. I'll be splitting the different renovation areas up into separate blog posts over the next few weeks so be sure to check back for those. Below is an aerial image of the old dairy barn before any renovations were made. The image below is a blueprint of the multi-purpose facility that the calving barn becomes after all renovation phases are complete. One of the reasons we decided to repurpose this barn into a calving facility is because of its location. This barn is the closest facility to our farm manager's (Greg) house. Having the barn close to Greg maximizes efficiency of his time. Dr. Higgins designed and helped us renovate this structure to incorporate loose housing for the animals during calving season, which allows us to better manage the herd during this critical time. Below are some pictures of what the barn floor looked like before. (You can click on an image to enlarge it) The existing barn floor was just a natural dirt floor. The Eden Shale soil has a very high clay content, so the floor stayed wet and would create the spires and holes that you see in the picture. When the floor dried out it was as hard as concrete and the cattle couldn’t even walk on the flooring. During construction we left the old milking parlor intact. There is an existing concrete ledge in the corner near the milking parlor that we also retained and used it as a place to put our squeeze chute. Having the chute at the calving barn allows us to be able to pull a calf, or to milk a cow if we need to. We dug out the old dirt floor down to solid soil and then installed Geotextile filter fabric with about 6 inches of dense grade aggregate (DGA) on top of it. Everything was then compacted with a plate compactor. On top of the DGA we laid down the Geo-Grid interlocking pieces. These pieces all fit together to create a honeycomb interconnected floor. The Geo-Grid is then backfilled with DGA. This is now the completed flooring install and is ready to have bedding put on top of it. On top of that concrete pad by the milking parlor, we added a head chute in case we ever have to pull a calf, help a calf to start nursing, etc. Lastly, we put 8 inches of wood shavings on top of the Geo-grid. You'll notice that we installed new gates and reconfigured them to better facilitate calving in the barn. The area under roof is not designed to house the entire herd. Pens consisting of various sizes are used based on need. Occupancy is rotated between first calf heifers and second calf heifers that have just calved or will soon calve. The concept is to provide a dry, clean bedding area to monitor calves and make sure the heifers take to the calves. We have the first calf heifers in a field right beside the barn. Our goal for the heifers is to have them calve in the barn. If they calve in the pasture, they get moved into the barn and spend about 24 hours there getting dried off, confirming that they have nursed, and just making sure they are strong and viable before we turn them out. We ear tag the calves and turn the pairs out to a different pasture as they are able. The design allows approximately 25 percent of the herd to use the indoor facility at one time. This constant flow of cows and calves through the barn has worked very well and the animals are not spending enough time in the barn to create a big mess. The renovated flooring creates a much better surface than the previous dirt floor, and it provides more support and less moisture for those new calves.. The image below was taken during the first year of rotating pairs through the barn. You can see that the sawdust is still providing clean and dry bedding for the calves. We add straw for clean bedding as necessary, but that is minimal. This facility allows the calves to get out of the mud, dry off, and get a strong start. It has now been 4 years since we completed the renovation and all of our heifers have calved in this barn each year. We have not added any additional bedding since the renovation, and we have not cleaned it out yet. This is due to the new pervious flooring, which allows for the moisture to move down away from the bedding, allowing it to dry out. This is a huge advantage as to not having to spend money on additional bedding year to year, and it saves the time of not having to clean the barn out and re-bed it. If you are considering renovating the flooring inside of a structure, I would highly recommend you look at the benefits of using the Geo-grid. For about the same cost of concrete you can install this style of floor and maximize the life of your bedding, saving you time in the long run. All of the filter fabric and the Geo-grid was purchased from Site Supply in Lexington. Be sure to check back for more blog posts on the dairy barn renovations. You can also subscribe to the blog and receive emails when new blog posts are added! Click the button below to subscribe

Comments are closed.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed