|

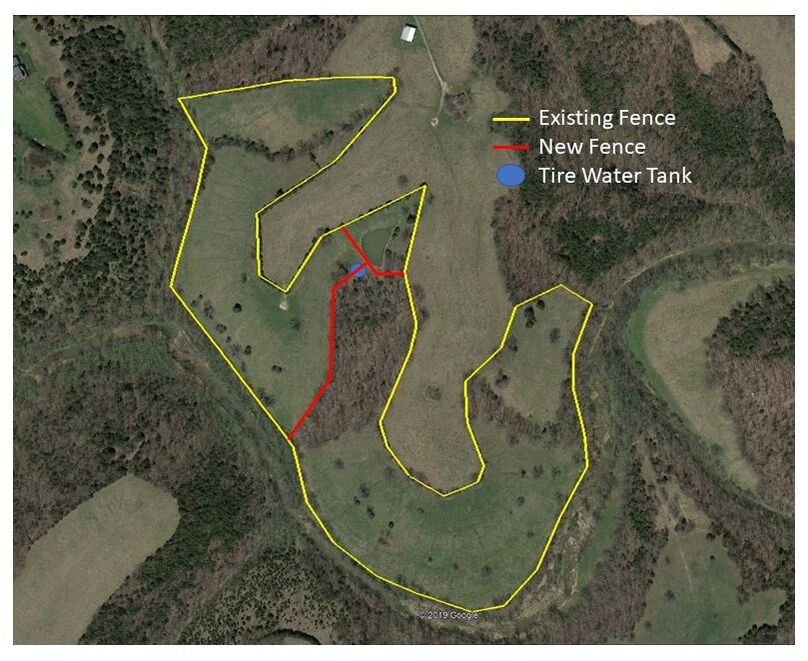

There are two different types of projects. There is the type that are most important and get first priority in both funding and implementation. Then there are the less critical projects, that while still would be a good practice, inevitably get shuffled to the back burner. At Eden Shale we took advantage of the good weather over the Christmas break to tackle one such project. It’s labeled as Field Number 45 on the Eden Shale Farm Map. It is a somewhat steep, horseshoe shaped field that measures 40 acres. In terms of pastures on the farm, it’s one of our largest. The only source of water in this field is an existing pond. It is a fairly deep pond and is still a reliable source to water cattle in the summer. Our plan for this project was simple. We wanted to develop the pond and put a large 8 foot tire water tank below the pond dam. Then, fence the pond off so the cattle didn’t have access into it, and run a fence down the center of the field splitting both it and the tire water tank. This project helped solve two seasonal issues. First, it gives us an additional field which allows us to better manage our rotational grazing during the summer months. And in the winter, it gives us a safer watering location, eliminating the threat of cattle falling through ice of the frozen pond. Fencing the cattle out of the pond and allowing a buffer strip should also increase the effective life span of the pond by reducing both bank erosion and the amount of sediment entering through surface water runoff. The installation process was similar as the other tire tanks that we have installed on the farm. This tire has geotextile fabric and dense grade rock under it. The pad around the tank is also fabric and dense grade gravel spread a minimum of 8 inches thick. The inside of the tire was poured with Sakrete as this tire was not accessible with a concrete truck. The supply line for the tank was ran around the side of the pond following the waters natural overflow path. The line was buried below the frostline to avoid freezing. With the tire being below the pond, this effectively creates a siphoning effect. It also allowed us to avoid putting the supply line directly through the dam which could develop a leak over time. The graphic shows the general layout of the field, the water tank, and the new fencing that divides it. Following construction, the tire tank is operational and was put into immediate service. We are looking forward to utilizing this new system throughout the year.

You know, sometimes it’s nice to get one of those back burner projects completed… Comments are closed.

|

Archives

June 2024

Categories

All

Welcome |

CONTACT US |

EMAIL SIGN UP |

|

Eden Shale Farm

245 Eden Shale Rd. Office: (859) 278-0899 Owenton, KY 40359 Fax: (859) 260-2060 © 2021 Kentucky Beef Network, LLC.. All rights reserved.

|

Receive our blog updates

|

RSS Feed

RSS Feed